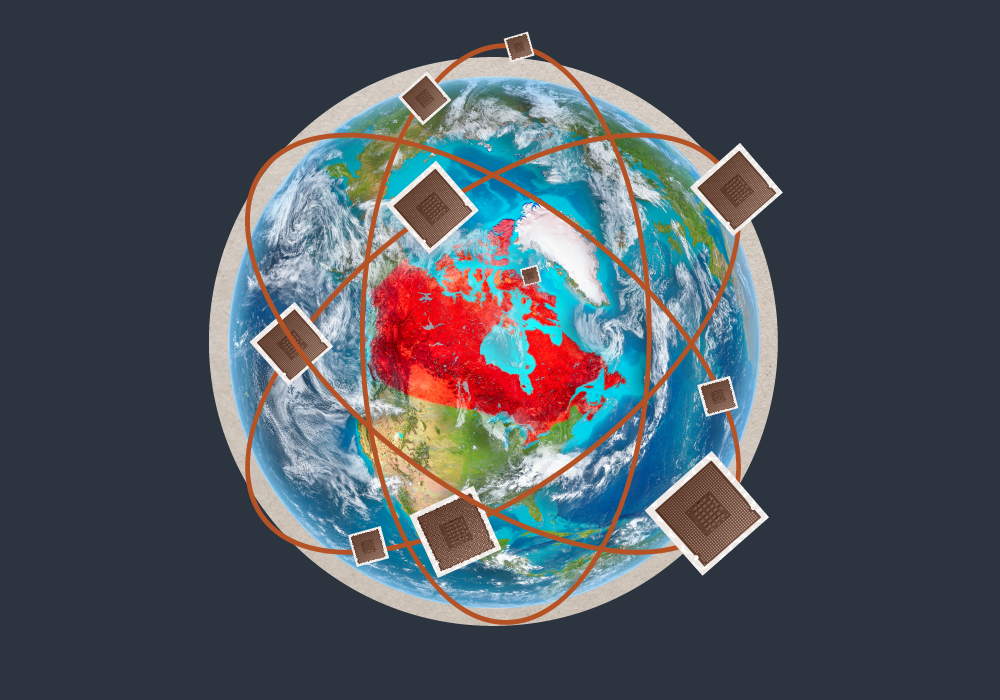

Is the domestic production of microchips a national security imperative? With the prevalence of semiconductors, or chips, in so many of our goods, the global chip shortage has caused a re-examination of business as usual for both industry and governments. Why are billions of dollars being poured into microchip manufacturing facilities around the world and what role does Canada play?

A Brief Overview of the Global Microchip Shortage

If a very brief and simplified recap of the factors leading to the global microchip shortage is in order, then here it is: the pandemic caused vehicle manufacturers to anticipate low demand and adjust their microchip orders accordingly. Work-from-home measures led to a spike in demand for consumer electronics and, thus, chips. When auto manufacturers eventually came calling, the capacity to meet their needs had been partially reallocated. Other compounding factors include pandemic-related factory shutdowns, shipping issues, a Japanese plant fire,1 and a strain on neon supplies (a key component in microchips) owing to the war in Ukraine.2 Much like the pandemic itself, analysis amongst supply chain professionals has failed to create a clear consensus on when, or if, we’ll be able to consider the chip supply problem a thing of the past.

Technological Sovereignty and the Importance of the Chip

Will future generations recall the current chip-conundrum as a temporary economic inconvenience, or a wake-up call for a more critical situation? The term ‘technological sovereignty’ is being used by those warning of potentially dire circumstances for nations that are unable to ensure a consistent supply of chips.

It may be no exaggeration to suggest that microchips are key to economic and military independence. In fact, with the role of chips in medical devices, they’re literally a matter of life and death.

Goldman Sachs has identified 169 different industries impacted by the shortage.3 Typical new vehicles use approximately 1400 microchips and it’s worth noting that both Ford and GM idled plants at points during the chip crisis.4

“It’s easier to say what isn’t being affected,” writes Stephen Shankland for CNet. “Just about anything with a power cord these days uses chips, so the shortage has hit cameras, microwave ovens, TVs, pacemakers, washing machines and more.”5

“The problem,” says semiconductor analyst Gaurav Gupta, “is if that 10-cent chip is missing, you can’t sell your $30,000 car.”6

Military technology is no exception. The dilemma that would face a country that found itself in military conflict with a country upon whom they relied for microchips is obvious.

“We don’t want to create a situation where the United States, which created the semiconductor industry and Silicon Valley, would be completely dependent on other nations for that product,” said Al Thompson, who leads Intel’s US government relations.5

Challenges of Microchip Manufacturing

Microchip manufacturing may be essential, but it’s neither cheap nor fast. Intel has invested $20B(USD) in two new production facilities in Arizona, but mass production won’t begin until 2024.5 A similar investment has been announced for Ohio. The US House of Representatives and Senate have been sorting through details related to a massive subsidy package aimed at increasing US production.7 The European Union’s ‘Chips for Europe Initiative’ seeks to do likewise.5

“When you go back to the origins of the industry, the majority of the capacity was in the U.S. and then it shifted outside,” professor of Manufacturing and Logistics Morris Cohen told ABC News. “Now, there’s a big push to re-shore that manufacturing and bring it back, and it’s not just a business decision…it’s a highly politicized decision.”8

Canada’s Role in Microchip Manufacturing

Where does this leave Canada? While investments made in our microchip manufacturing industry may currently pale in comparison to those made elsewhere, we do enjoy certain advantages. As Invest Canada points out, Canada is already a home to massive producers such as TSMC, Samsung, and Intel, who operate alongside homegrown producers and innovators such as MOSAID and WeavAir.9

“(The companies) are drawn by Canada’s trade agreements, affordable utilities, highly skilled workforce, institutional support and leadership in artificial intelligence” says Invest Canada.9

Sourcing Microchips Through Supply Chain

No article about pandemic era supply chain issues would be complete without the obligatory nod to the benefits of ‘just in case’ inventory, as opposed to the previously favoured ‘just in time’ system. The microchip shortage took many by surprise and even Apple, with their purchasing clout and famous dedication to supply chain management, were forced to delay the launch of their iPhone 12 by several weeks.5

Manufacturing companies, like governments, are being forced to look several years down the road, and introduce ‘an abundance of caution’ into their procurement and inventory philosophies. Their very ability to operate may depend on it.